Ever since designed by Takeshi Nii from Japan in 1970, Nychair X has been acknowledged around the world as a folding chair masterpiece. The simple, elegant, and functional design befitting for any occasion is rooted in Japanese lifestyle and cultural heritage – where the center of gravity is lower and rooms serve multiple functions. Still today, the chair is appreciated and cherished by users worldwide for the quality uniquely imparted in Japan to deliver ultimate sitting comfort.

As the time-tested tool crafted for better living, Nychair X will continue to deliver superior comfort and flexibility of usage to users around the world with quality uniquely imparted in Japan.

Main features of Nychair X

1. Foldable

The chair can be easily folded into a thickness of as little as 15-22 cm, which can still stand on its own and can be stored away into a narrow space. Folded chair can also be carried more easily, and with a weight of just 6-6.5 kg, it can be handled with ease by most users.

2. Comfortable

The angles and materials of each seat, armrest, and backrest are carefully crafted to support the body. The fabric adjusts itself to the shape and weight of the user's body, embracing it gently.The soft seat surface and smooth wooden armrests are pleasant to touch.

3. Carefully made in Japan

Nychair X may be built with simple parts, but they are crafted with precision that can only be achieved with advanced technologies. The manufacturing processes are run in Japan.

4. Repairable

Timeworn seats can be removed and replaced. Screws and pipes can be repaired with replacement parts so the chair can serve you for years.

See replacement parts

The designer and the design director

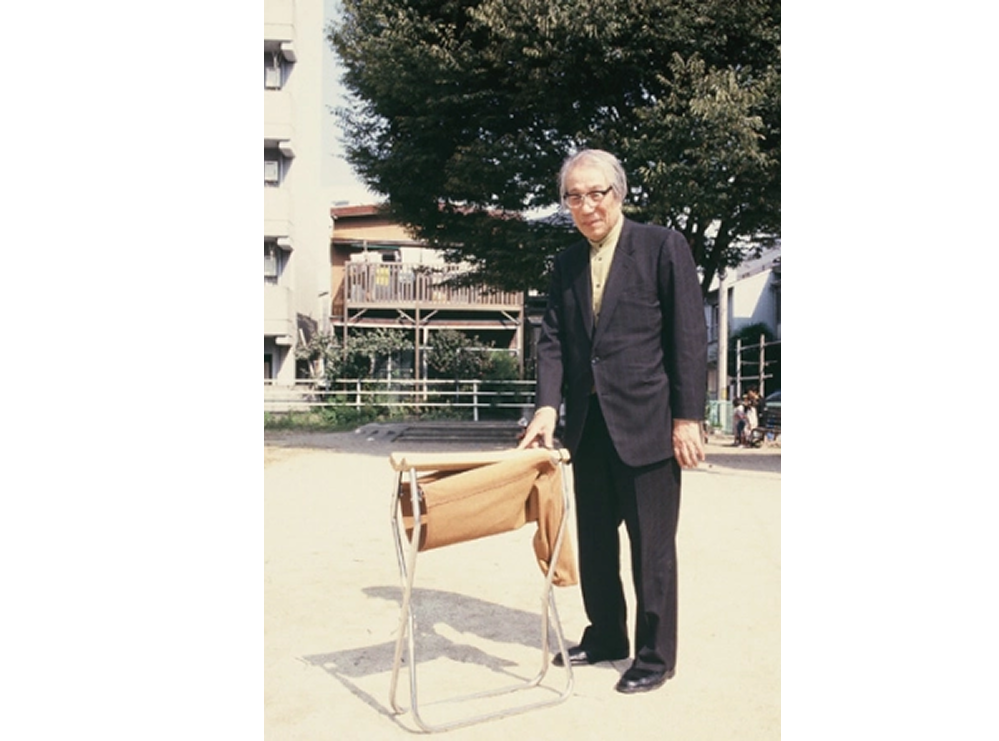

Takeshi Nii

Takeshi Nii is a Japanese designer who devised Nychair X. He was born as a third-generation member of a family in Tokushima Prefecture that has produced and sold training gear and equipment for kendo and judo. Later he had found his passion for furniture, especially folding one, which he has perfected during his active years. Convinced that “true chairs should be affordable and useful as a tool, without compromising comfort”, he strived to “design a chair loved by everyone, like Japanese curry rice”, one of the most common comfort foods.

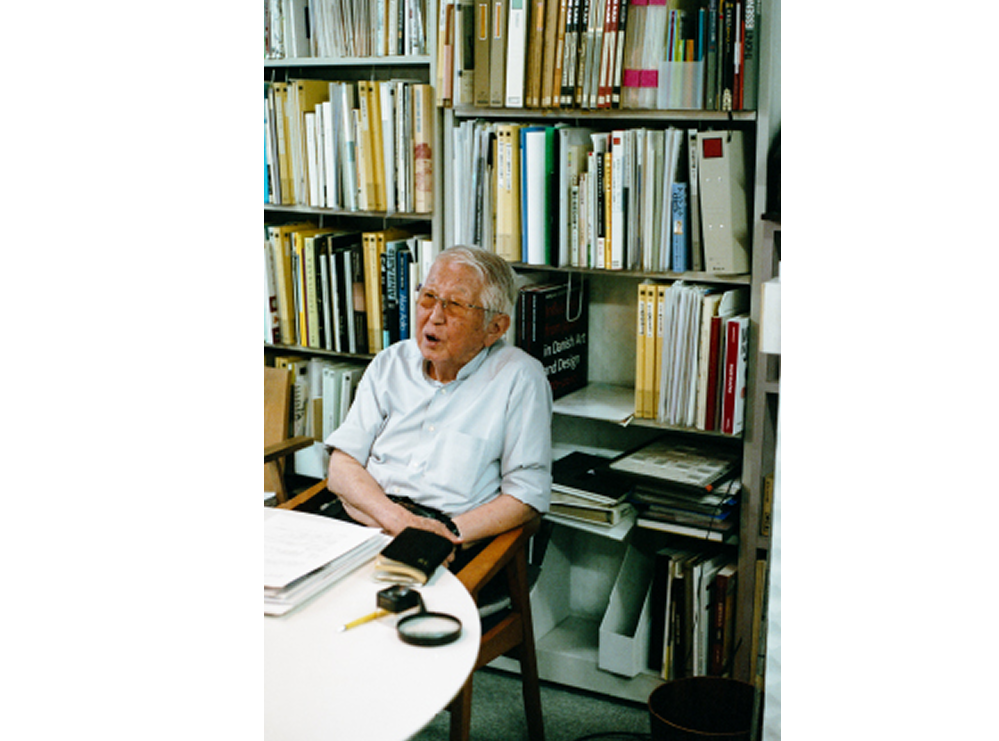

Makoto Shimazaki

Makoto Shimazaki studied furniture design and is a leading expert on Scandinavian design in Japan. He has named the Nychair series and supervises its design. He values Nychair X for meeting all the six conditions expected of good chairs – namely, 1. sitting comfort, 2. durability, 3. light weight, 4. affordable price, 5. attractive shape, and 6. beauty and stability retained in a folded form.

Learn about Nychair X part by part

Seat fabric

In order to maintain the strength necessary to comfortably support body weight when seated, the seat is made using twill weaving technique, the same as used in denim. To recreate the Nii’s idea of “softness as if it was washed once”, the fabric’s surface undergoes a process where it is scratched to make it fluffier. Usually, the dyeing and water-repellent finishing are done at the same time after weaving, but our process is different: after dyeing, the fabric first undergoes the fluffing process, and then a water-repellent finishing is applied. Takeshi Nii developed this unique seat fabric with inspiration from kendo uniforms and equipment bags. It is said he soaked the fabric in water and checked the tension with his feet. Currently, production is divided between two factories: one in Kurashiki, Okayama prefecture, and another, currently the main one, in Takashima, Shiga prefecture. The weaving, processing, and dyeing are supported by a technological insight of multiple workshops to manufacture the final fabric.

Armrests

Wood was used for armrests – the parts that are the most frequently touched – from the beginning, stemming from the thought that natural materials have a calming and grounding effect. The structure of a human arm was taken into consideration to design armrests that prevent fatigue. The armrests are attached by only two screws, so even a small error in hole positioning might affect the angle of the frame and have a huge impact on the level of comfort. After trial and error, we have introduced a computer-controlled dedicated processing machine for Nychair X. Because the machine does everything from shaping the wood to making holes in the armrest, it has improved cost-efficiency, production volume, and precision.

The wood is finished differently across the series, and to ensure the color and shades of wood are coordinated in both armrests in transparent wood finishes of Natural and Soap Finish, the final control is performed with human eyes.

Seat pipes

In Nychair X, the seat frame is connected to the armrests by one type of screw in four places, which requires precise calculations to ensure the placement of the screws is aligned. Previously used cutting drills were replaced with lasers to prevent difficulties with assembly. The change made it possible to eliminate subtle position changes during processing and residue inside and outside the pipe, which were the reason for problems in early Nychair X when threading the screws.

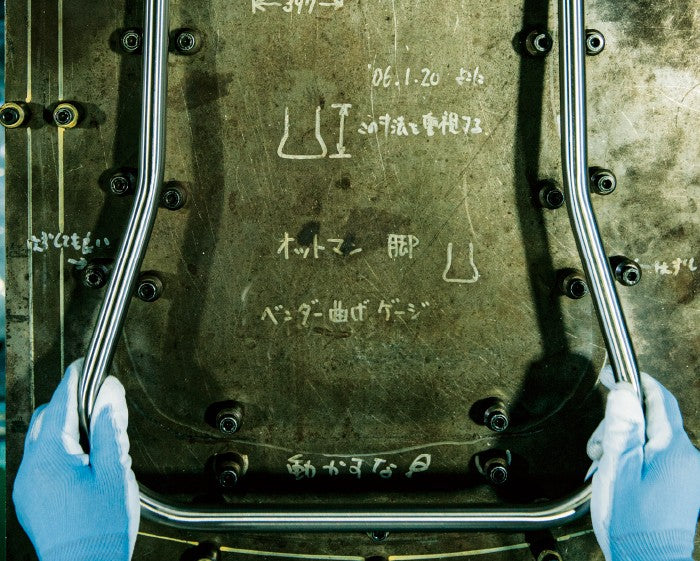

Leg pipes

The pipes are formed by folding a stainless steel sheet into a tubular shape and welding the connecting ends together. To prevent spoiling the beauty of the legs, the inside of the hole is inspected, and the processing is done after making sure the welding marks are facing the inside.The pipes are finished with a hairline matte surface to prevent excess shine and allow the chair to blend with an interior better. Additionally, it also helps conceal any scratches on the pipes that might develop during continuous usage. There is no need for maintenance, such as repairs or coating, and the chair can be loved for many years while retaining its beauty.

Screws

Since it was first released, Nychair X has been made to be easy to assemble and disassemble; only cross-head screws are used, allowing assembly with a common Phillips screwdriver. However, because the screws connecting the two leg pipes were prone to loosening over time, we have used screws that tighten more firmly for elements not requiring assembly. Nychair X 80 has even more moving parts, and compared to Nychair X, the screws are more vulnerable to loosening due to the chair's construction. To address this issue, the screws are coated with a special lubricant, which makes it harder to loosen them.

The new generation model uses stainless steel instead of regular steel to avoid breakage due to deterioration and prevent rust, which can make a screw unmovable.

Efforts towards sustainable manufacturing

Getting things we become attached to and continuing to use them for a long time not only enriches our everyday lives, but also contributes to reducing waste and the burden placed on the environment by the production processes. To allow Nychair X to be enjoyed for longer by repairing any damages made during continuous use, we will be introducing additional replacement parts in our store. Please contact us for more information. We are trying our best to allow everyone to enjoy Nychair X as “a tool for good living that will always be loved” over the generations, passed from parent to child, from child to grandchild.